LIST OF ABSTRACTS AND INDEX

PLENARIES. 25

New opportunities

for granular matter research. 26

Heinrich Jaeger

University of Chicago -

United States

DEM-based

metamodeling - the booster for design of bulk solids handling equipment?. 27

Dingena Schott

Delft University of

Technology - The Netherlands

Flow of bulk

materials into small confined spaces: characterisation and modelling. 28

Chuan-Yu (Charley) Wu

Department of Chemical and

Process Engineering, University of Surrey, Guildford, GU2 7XH, UK

The Rheology of

Granular Materials: from Fundamentals to Applications. 29

Raffaella Ocone

Heriot-Watt University,

United Kingdom

Interaction between

dry grains and liquids inspired by industrial processes. 30

Pierre Jop

Glass Surface and

Interfaces, CNRS/Saint-Gobain, France

Potential and

limitations of CFD and DEM simulation in the design of orally inhaled drug

products. 31

Andrea Benassi

Chiesi Farmaceutici Spa, Parma (Italy)

Characterization of

feedstock materials for powder bed fusion Additive Manufacturing. 32

Jochen Schmidt1,2

1Institute of Particle Technology, Department of

Chemical and Biological Engineering, Friedrich-Alexander-Universität

Erlangen-Nürnberg, Erlangen, Germany

2Colloborative Research Center 814 “Additive

Manufacturing”, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen,

Germany

WEDNESDAY, 6 JULY

2022 -

TUSAIL SYMPOSIUM... 33

Using a commercial

rheometer to determine a particle-particle cohesion model 34

Christine M. Hrenya

University of Colorado -

United States

Benefits and open problems in

coarse-graining methods for DEM-based simulations of fluid-particle systems. 35

Erasmo S. Napolitano, Francesco P. Di

Maio, Alberto Di Renzo

DIMES Department,

University of Calabria, Via P. Bucci, Cubo 42C, 87036 Rende (CS), Italy

Comparison of

CFD-DEM and TFM approaches for the simulation of the single- and multiple-spout

fluidized beds. 36

Behrad Esgandari1, Stefanie Rauchenzauner2,

Christoph Goniva3, Rouven Weiler4, Simon Schneiderbauer1,2

1Department of Particulate

Flow Modelling, Johannes Kepler University Linz (JKU), Linz, Austria

2Christian Doppler Laboratory for Multi-Scale Modelling

of Multiphase Processes, Johannes Kepler University Linz (JKU), Linz, Austria

3DCS Computing GmbH, Linz, Austria 4 BASF

SE, Ludwigshafen, Germany

Modelling

fluidization by recurrence CFD (rCFD) 37

Varun Dongre1,

Stefan Pirker1

1Department of Particulate Flow Modelling, Johannes

Kepler University, Linz, Austria

WEDNESDAY, 6 JULY

2022 -

COMPUTATIONAL MODELS. 38

DEM calibration of

cohesive bulk materials. 39

Corné Coetzee, Otto Scheffler

Department of Mechanical

& Mechatronic Engineering, University of Stellenbosch, Stellenbosch, South

Africa. 39

DEM model for the

quantitative prediction of cohesive powder (ESKAL) flowability. 40

Maheandar Manokaran1, Martin Morgeneyer2,

Christophe Bressot3

1Génie de procédés Industriels, Université de

Technologie de Compiègne (UTC), Compiègne, France

2Génie de procédés Industriels, Université de

Technologie de Compiègne (UTC), Compiègne, France

3Direction des Risques Chroniques, Institut National de

l'Environnement Industriel et des Risques (INERIS), Verneuil en Halatte, France

DEM simulation of moist sand over a transfer point 41

Otto Scheffler, Corné Coetzee

Dept. of Mechanical and

Mechatronic Engineering, University of Stellenbosch, Stellenbosch, South Africa

DEM modelling of

elastic-plastic contact behavior for cohesive powders. 42

Robert Hesse, Sergiy Antonyuk

Institute of Particle

Process Engineering, Technical University of Kaiserslautern, Kaiserslautern,

Germany

An SPH study on the

compaction of soft deformable grains. 43

Francisco Goio, Stefan Radl

Institute of Process and

Particle Engineering, Graz University of Technology, Graz, Austria

WEDNESDAY, 6 JULY

2022 -

MECHANICAL BEHAVIOR OF BULK MATERIALS. 44

The role of

Archimedes number in particulate bed void-fraction and flowability. 45

Haim Kalman1,2 and Dmitry

Portnikov1

1

The Laboratory for Conveying and Handling of Particulate Solids, Department of

Mechanical Engineering, Ben-Gurion University of the Negev, Beer Sheva 84105,

Israel.

2

Aaron Fish Chair in Mechanical Engineering – Fracture Mechanics, Israel.

Case Study: Silo and

System Design for Fibrous Recycling Materials. 46

Hans Schneider

Zeppelin Systems GmbH,

Friedrichshafen, Germany

A combined DEM and CNN

model for characterizing and evaluating the performance of ball mills. 47

Yaoyu Li, Runyu Yan *

1 School of Materials Science and Engineering, UNSW

Sydney, NSW 2052, Australia

Rheology of cohesive

powder mixtures. 48

1School of Chemical and Process Engineering, University

of Leeds, Leeds, UK

2UCB Pharma, Chemin du Foriest B-1420 Braine l'Alleud,

Belgium

3School of Mechanical and Power Engineering, Nanjing

Tech University, Nanjing 211816, China

4Fluid Comp, Leeds, UK

Experimental study

of granular heap flow under vertical vibrations. 49

Fabian2, Kiesgen de

Richter Sébastien1

1LEMTA, Université de Lorraine, CNRS, F-54000 Nancy,

France

2Institute of Particle Process Engineering, Technische

Universität Kaiserslautern (TUK), Kaiserslautern, Germany

How a granular pile becomes a glass. 50

Stefan Boettcher *1, Paula A. Gago+2

1Department of Physics, Emory University, Atlanta, USA;

2Department of Earth Science and Engineering, Imperial

College London

Density instabilities and compaction

efficiency in a tapped granular pile. 51

Paula A. Gago*1, Stefan

Boettcher+2

1Department of Earth Science and Engineering, Imperial

College London;

2Department of Physics, Emory University, Atlanta, USA

Optimization of a

flighted rotary drum cross-sectional characteristics. 52

Dmitry Portnikov1, Gennady Ziskind1,2 and Haim

Kalman1,3

1The Laboratory for Conveying and Handling of

Particulate Solids, Department of Mechanical Engineering, Ben-Gurion University

of the Negev, Beer Sheva 84105, Israel.

2Anne Tanenbaum Chair in Engineering Thermodynamics,

Israel.

3Aaron Fish Chair in Mechanical Engineering – Fracture

Mechanics, Israel.

Comparison of

different test methods for the flow property evaluation of fibrous materials. 53

Steffen Beitz1,2, Harald

Zetzener1, Hans Schneider2, Arne Kwade1

1Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

2Zeppelin Systems GmbH, Friedrichshafen, Germany

Reverse Janssen

effect in narrow granular column. 54

Shivam Mahajan1, Michael

Tennenbaum2, Sudhir N. Pathak1, Devontae Baxter2,

Xiaochen Fan2, Pablo Padilla2, Caleb Anderson2,

Alberto Fernandez-Nieves,2,3,4, Massimo Pica Ciamarra1,5

1Division of Physics and Applied Physics, Nanyang

Technological University, Singapore

2School of Physics, Georgia Institute of Technology,

Atlanta, Georgia, USA

3Department of Condensed Matter Physics, University of

Barcelona, Barcelona, Spain

4ICREA-Institució Catalana de Recerca i Estudis Avançats,

Barcelona, Spain

5CNR–SPIN, Dipartimento di Scienze Fisiche, Università di Napoli

Federico II, Napoli, Italy

WEDNESDAY, 6 JULY

2022 -

SILO DESIGN.. 55

Proposal to

structure silo failure analysis. 56

Harald Wilms1, Hans

Schneider2, Christian Dietsche2

1Wilms-ITC, Innovation-Technology-Consulting, Bremen,

Germany

2Zeppelin Systems GmbH, Friedrichshafen, Germany

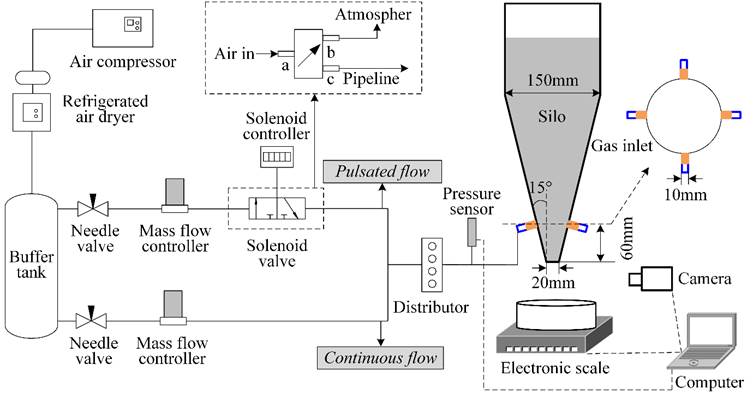

Process

intensification of hopper discharge of cohesive powders based on modulated

pulsed airflow.. 57

Haifeng Liu*, Lizhuo Zhu, Haifeng Lu,

Xiaolei Guo

Shanghai Engineering

Research Center of Coal Gasification, East China University of Science and

Technology, China

Parametric study and

flow regime map for planar silos and hoppers. 58

Evgeny Rabinovicha,c*,

Haim Kalmanb, Per F. Petersonc

a Nuclear Research Center Negev (NRCN), Beer Sheva,

Israel

b Dept. of Mechanical Engineering, Ben-Gurion University

of the Negev, Beer Sheva, Israel

c Department of Nuclear Engineering, University of

California, Berkeley 94720-1730, US

*Corresponding author: erabinovich78@gmail.com

WEDNESDAY, 6 JULY

2022 -

PNEUMATIC AND MECHANICAL CONVEYING.. 59

Analysing impact

forces & overcoming speed, heat and pressure issues in high capacity belt

support applications. 60

Cameron Thomas Portelli1, Charles Camden Pratt2

1Engineering Department, Kinder Australia, Melbourne,

Australia

2Operations & Sales Department, Kinder Australia,

Melbourne, Australia

Motion resistances

in trough chain conveyors. 61

Andre Katterfeld

Institute of Logistics and

Material Handling Systems,

Otto-von-Guericke University Magdeburg, Germany

Understanding the total cost of

ownership of bulk solids handling systems: a new paradigm to reduce risks in

procurement of solids handling systems and equipment 62

Charles Williams, Mike Bradley

The Solids Handling And

Processing Association, UK

Refill strategy

optimization of a twin-screw feeder with DEM... 63

Peter Toson1, Johannes G.

Khinast1,2

1 Modeling and Prediction, Research Center

Pharmaceutical Engineering, Graz, Austria

2 Institute of Process and Particle Engineering, TU

Graz, Graz, Austria

Development of bulk

material dosing equipment using DEM... 64

Jan Nečas1,2, Jakub

Hlosta1,2, David Žurovec1, Jiří Rozbroj1,

Jiří Zegzulka1,2

1VSB-Technical University of

Ostrava, Faculty of Mining and Geology, 17. listopadu 15/2172, 708 33 Ostrava, Czech

Republic, EU

2VSB-Technical University of

Ostrava, CEET, ENET Centre, Bulk Solid Centre, 17. listopadu 15/2172, 708 33

Ostrava, Czech Republic, EU

Effect of particle

size distribution on frictional head loss in pipe flow of sand-water slurry. 65

Czech Academy of Sciences,

Institute of Hydrodynamics, Prague, Czech Republic

Exploring “Big Data”

on the effect of different materials on pressure drops in pneumatic conveying,

identifying bend and straight pipe losses and bend equivalent lengths. 66

MSA Bradley, T Deng

The Wolfson Centre for

Bulk Solids Handling Technology, University of Greenwich

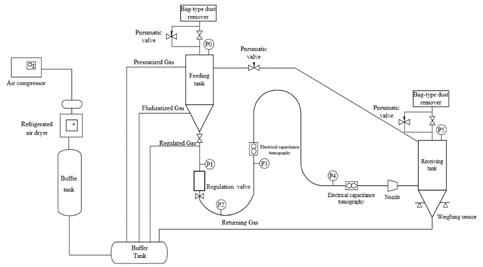

Study on

characteristics of flow rate regulation in the dense-phase pneumatic conveying

of pulverized coal 67

Haifeng Lu*, Hu Ruan, Xiaolei Guo,

Haifeng Liu

Shanghai Engineering

Research Center of Coal Gasification, East China University of Science and

Technology, China

Determining and

comparing breakage matrices to predict particle attrition in pneumatic

conveyors. 68

MSA Bradley, T Deng

The Wolfson Centre for

Bulk Solids Handling Technology, University of Greenwich

Pneumatic conveying of solids: scale-up

and design of long line systems. 69

Rizk Farid

R & D Solids Handling BASF Formerly, R & D Solids Handling BASF Formerly, Ludwigshafen, Germany. 69

WEDNESDAY, 6 JULY 2022 -

MULTIPHASE FLOW AND FLUIDIZATION.. 70

Confined-fluidization

as a way of improving CO2 capture by adsorption on solid sorbents. 71

R. Girimonte, F. Testa and M. Turano

Department of Computer

Engineering, Modeling, Electronics and Systems (DIMES), University of Calabria, I 87030 Arcavacata di Rende (Cosenza), Italy

Hydrodynamics of

pulse-assisted fluidization of cohesive powder. 72

Ebrahim H. Al-Ghurabi, Mourad

M. Boumaza, Mohammad Asif

Dept. of Chemical

Engineering, King Saud University, Riyadh, Saudi Arabia

Fluidization and

flow behavior of powder coatings when approaching their glass transition

temperature. 73

Helena Weingrill1,

Christina Reichart1, Timothy Aschl1, Denis Schuetz2

1Department of Rheometry, Anton Paar GmbH, Graz,

Austria

2R & D Rheometry, Anton Paar GmbH, Graz, Austria

Hydrodynamics of a

novel directly irradiated fluidized bed autothermal reactor for thermochemical

energy storage. 74

Stefano Padula1, Maurizio

Troiano1,2, Claudio Tregambi2,3, Roberto Solimene2*,

Piero Salatino1

1Dipartimento di Ingegneria Chimica dei Materiali e della

Produzione Industriale, Università degli Studi di Napoli Federico II, Napoli, Italy

2Istituto di Scienze e Tecnologie per l'Energia e la Mobilità

Sostenibili (STEMS), Consiglio Nazionale delle Ricerche, Napoli, Italy

3Dipartimento di Ingegneria, Università degli Studi del

Sannio, Benevento, Italy

The role of

temperature and moisture on polymer materials for additive manufacturing, and

their implications for the process. 75

Denis Schütz1, Helena

Weingrill1

1R&D Rheology (Anton Paar Gmbh, Graz Austria)

Classification of

fine gas born particles in superposed electric and acoustic fields. 76

Krischan Sandmann1, Udo

Fritsching1,2

1Leibniz-Institut für Werkstofforientierte Technologien

- IWT, Badgasteiner Straße 3, 28359 Bremen, Germany

2University of Bremen, Faculty of Production

Engineering, Bibliothekstraße 1, 28359 Bremen, Germany

Investigation of the

wet contact behavior of particles in CFD-DEM simulations of a rotor granulator. 77

Philipp Grohn1, Tobias

Oesau2, Stefan Heinrich2, Sergiy Antonyuk1

1Institute of Particle Process Engineering, Technische

Universität Kaiserslautern, Kaiserslautern, Germany

2Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology, Hamburg, Germany

An experimental investigation on

channelized granular flows. 78

Luca Sarno1, Maria

Nicolina Papa2, Paolo Villani2

1Institute of Fluid Dynamics, Dept. of Mechanical

Engineering, TU Darmstadt, Darmstadt, Germany

2 Department of Civil Engineering, University of

Salerno, Salerno, Italy

Neural network-based

filtered drag model for cohesive gas-particle flows. 79

Josef Tausendschön1, Stefan Radl2, Sankaran

Sundaresan3

1Institute of Process and Particle Engineering, Graz

University of Technology, Graz, Austria

2 Institute of Process and Particle Engineering, Graz

University of Technology, Graz, Austria 3 Dept. of Chemical and

Biological Engineering, Princeton University, Princeton, USA

Terminal velocity

and drag coefficient for accelerating spherical particles. 80

Haim Kalman1,2, Dmitry

Portnikov1 and Erez Matana1

1

The Laboratory for Conveying and Handling of Particulate Solids, Department of

Mechanical Engineering, Ben-Gurion University of the Negev, Beer Sheva 84105,

Israel.

2

Aaron Fish Chair in Mechanical Engineering – Fracture Mechanics, Israel.

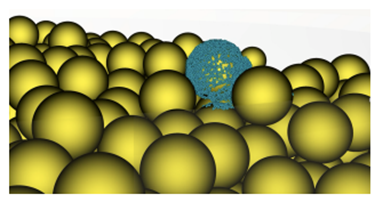

Investigation of

endogenous bubble-induced segregation of a single biomass particle in fluidized

bed reactors. 81

Stefano Iannello1,

Massimiliano Materazzi1

1Department of Chemical Engineering, University College

London, London WC1E 7JE, UK

Solids

mixing/segregation in high temperature dense gas-solid fluidized beds by

capacitance and pressure measurements. 82

Laura Molignano1, Maurizio Troiano1, Roberto

Solimene2*, Sina Tebianian3, Piero Salatino1,

Jean-Franҫois Joly3

1Dipartimento di Ingegneria Chimica, dei Materiali e della

Produzione Industriale, Università degli Studi di Napoli Federico II, Napoli,

Italy

2Istituto di Scienze e Tecnologie per l'Energia e la Mobilità

Sostenibili, Consiglio Nazionale delle Ricerche, Napoli, Italy

3Direction Conception Modélisation Procédés, IFP

Energies Nouvelles, Solaize, France

Efficiency of

stand-alone filters: effects of filter aperture and meshing design. 83

Paula A. Gago*1, Raphael

Blumenfeld1,2, Sheik Rahman3, Stephen Tyson4,

Peter King1

1Department of Earth Science and Engineering, Imperial

College London;

2Cavendish Laboratory Cambridge, UK;

3School of Petroleum Engineering, University of New

South Wales, Australia;

4Universiti Teknologi Brunei, Jalan Tungku Link, Gadong

BE1410, Brunei Darussalam

THURSDAY, 7 JULY 2022 -

COMPUTATIONAL MODELS. 84

Simulation of

hierarchical structure formation during spray drying using CFD-DEM coupling. 85

Silas Wolf, Nane Kühn, Carsten

Schilde

Institute for Particle

Technology, Technische Universität Braunschweig, Braunschweig, Germany

CFD-DEM simulations

of strongly polydisperse particulate solids in the cyclonic flow of dry powder

inhalers. 86

Francesca Orsola Alfano1 ,

Andrea Benassi2,3, Roberto Gaspari2 , Alberto Di Renzo1

, Francesco Paolo Di Maio1

1 DIMES Department, University of Calabria, Cosenza,

Italy

2 Chiesi Farmaceutici S.p.A., Parma, Italy

3 International School for Advanced Studies (SISSA),

Trieste, Italy

Using the Material

Point Method (MPM) to model bulk materials. 87

Corné Coetzee

Department of Mechanical

& Mechatronic Engineering, University of Stellenbosch, Stellenbosch, South

Africa

Multiscale modelling

of granular materials – Calibration of discrete particle models. 88

Thomas Weinhart1,2,

Mohammed Reza Vesal2, Raquel Weinhart-Mejia2, Donna Fitzsimmons2, Anthony R

Thornton1,2

1 Thermal and Fluid Engineering, ET, University of

Twente, Enschede, The Netherlands

2 MercuryLab, Enschede, The Netherlands

An in-depth study of

mixing and turning behavior of a compost pile using Discrete Element Method and

Big-Data analysis. 89

MSc. Mirkhagan Mustafazade1,

MSc. Mohsin Ajmal1, Prof. Dr. Andre Katterfeld1

1Institute of Logistics and Material Handling Systems,

OvGU Magdeburg, Magdeburg, Germany

An optimal

calibration procedure for the Discrete Element Method. 90

Farheez Mohamed1 , Elias

Daouk1 , Mikel Leturia1 , Elodie Beaunac1,2 ,

Anne Charlotte Robisson2 , Carine Ablitzer2 , Khashayar

Saleh1

1Université de Technologie de Compiègne, ESCOM, TIMR

(Integrated Transformations of Renewable Matter), Centre de recherche de

Royallieu, Compiègne, France

2CEA IRESNE/DEC/SA3E/LCU, Cadarache, France

Digital twins to

improve the calibration of DEM simulation of powder processes. 91

Aurélien Neveu1 , Benjamin

Jenkins2 , Dominik Werner2 , Andrei L. Nicusan2

, Christopher R.K. Windows-Yule2 , Geoffroy Lumay3

1 Granutools SPRL, Awans, Belgium

2 School of Chemical Engineering, the University of

Birmingham, Birmingham, UK

3 GRASP laboratory, CESAM research center, University

of Liege, Liege, Belgium

Robust estimation

and validation of contact parameters of iron ore for transfer chute simulation. 92

Guilherme P. De Oliveira, Rodrigo M.

De Carvalho, Henrique A. Peixoto, Luís Marcelo Tavares

Dept. of Metallurgical and

Materials Engineering, Universidade Federal do Rio de Janeiro, Rio de Janeiro,

Brazil.

Investigations of

abrasive sliding and impact wear – a DEM calibration approach. 93

Thomas Roessler, Andre Katterfeld

Chair of Material Handling

Systems, University of Magdeburg, Magdeburg, Germany

DEM simulations of

industrial scale granular chute flows. 94

Satyabrata Patro, Nikhil Kumar Meena,

Anurag Tripathi

Dept. of Chemical

Engineering, Indian Institute of Technology, Kanpur, India

Predicting time

dependent behavior of surface granular flows. 95

Anurag Tripathi1 ,

Satyabrata Patro1 , Sumit Kumar2 , Anubhav Majumdar1

1Dept. of Chemical Engineering, Indian Institute of

Technology Kanpur, Kanpur, India

2Dr. Reddy's Laboratory, Hyderabad, India

THURSDAY, 7 JULY 2022 -

MATHEGRAM SYMPOSIUM... 96

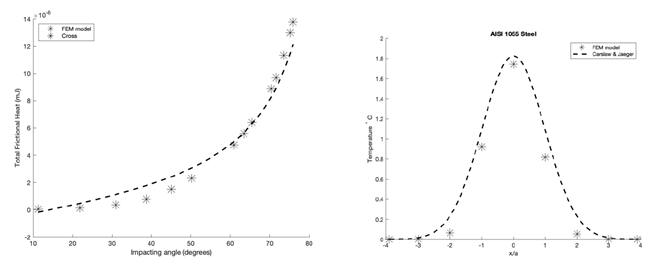

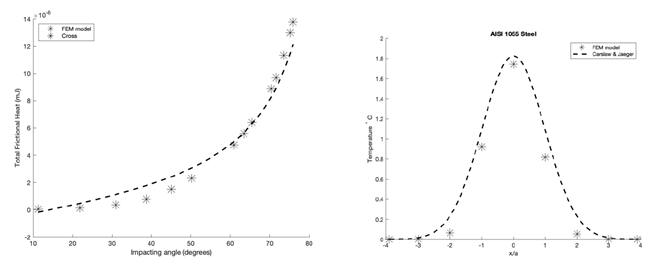

Heat generation by friction and deformation during an

oblique impact 97

Francisco Kisuka1, Colin Hare1,2, Chuan-Yu Wu1

1Dept. of Chemical and Process engineering, University

of Surrey, Guildford, United Kingdom

2 School of Chemical Engineering, Newcastle university,

Newcastle upon Tyne, United Kingdom

Calibration of

CFD-DEM heat transfer model using packed bed experiment 98

Aman Rastogi1, Colin Hare2, Vincenzino

Vivacqua1

1JMTC, Johnson Matthey, UK

2School of Engineering, Newcastle University, UK

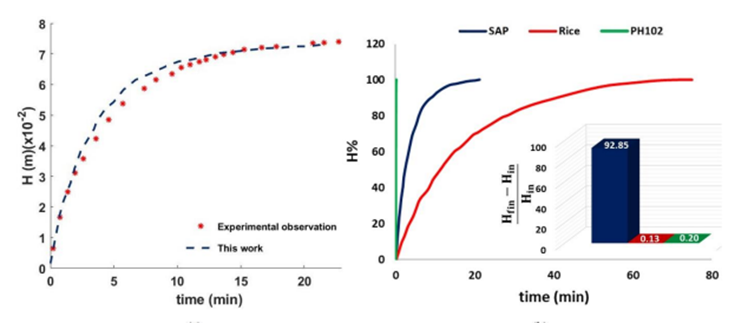

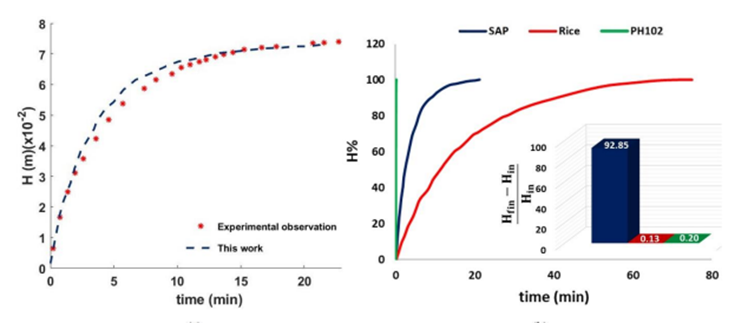

DEM modelling of

granular material swelling. 99

Domenica Braile1 , Colin

Hare1,2 , Chuan-Yu Wu1

1Dept. of Chemical and Process Engineering, University

of Surrey, Guildford, United Kingdom

2School of Chemical Engineering, Newcastle University,

Newcastle upon Tyne, United Kingdom

Modeling

particle-scale deformation and heat conduction for a highly dense granular

system with finite volume method. 100

Ranjan Dhakal1,

Philip Cardiff2, Stefan Radl1

1 Institute for Process and Particle Engineering, Graz

University of Technology, Inffeldgasse 13/3, 8010 Graz, Austria

2 School of Mechanical and Materials Engineering,

University College Dublin, Belfield, D4, Dublin, Ireland

CFD-DEM model for

high-temperature processes. 101

Jelena Mačak1,2,

Christoph Goniva1, Stefan Radl2

1 DCS Computing GmbH, Linz, Austria

2 Institute of Process and Particle Engineering, Graz

University of Technology, Graz, Austria

Sources of error

when measuring the hydraulic conductivity of a granular material at different

temperatures. 102

Marina S Bortolotto1, David M G Taborda1,

Catherine O'Sullivan1

1Department of Civil and Environmental Engineering,

Imperial College London, London, UK

Fundamental basis

for a novel approach to indirectly measure the effective thermal conductivity of

granular materials. 103

Tokio Morimoto1,

Catherine O'Sullivan1, David M. G. Taborda1

1Dept. of Civil and Environmental Engineering, Imperial

College London, London, UK

The effect of

temperature on the spreading of powder layers in selective laser sintering. 104

Sina Zinatlou Ajabshir *, Diego

Barletta, Daniele Sofia, Massimo Poletto

Dipartimento di Ingegneria Industriale, Università degli

Studi di Salerno, Fisciano SA, Italy

In-situ monitoring

and modeling of single-layer selective laser sintering of polyamide powders. 105

Balaji Soundararajan1, Daniele Sofia1,2, Diego

Barletta1, Massimo Poletto1

1Dept. of Chemical Engineering, University of Salerno,

Salerno, Italy

2Sense square Srl, Salerno, Italy

A numerical study of

heat transfer mechanisms in dense particulate systems using DEM... 106

Rafael Rangel1 ,

Alessandro Franci1 , Alejandro Cornejo1 , Francisco

Zárate1 , Eugenio Oñate1

1 International Center for Numerical Methods in

Engineering (CIMNE), Universitat Politècnica de Catalunya (UPC), Barcelona,

Spain

Analysis of

sintering of ceramic powder systems by in-situ synchrotron nano-tomography. 107

Aatreya Manjulagiri Venkatesh1

, Didier Bouvard1 , Pierre Lhuissier1 , Julie Villanova2

1Univ. Grenoble Alpes, CNRS, Grenoble INP, SIMAP, 38000

Grenoble, France

2ESRF - The European Synchrotron, 71 Avenue des

Martyrs, 38000 Grenoble, France

Modeling grain

growth and arbitrarily shaped particles in sintering with the discrete element

method. 108

Brayan Paredes-Goyes1 ,

David Jauffres1 , Christophe L. Martin1

1Univ. Grenoble Alpes, CNRS, Grenoble INP, SIMaP,

Grenoble, France

THURSDAY, 7 JULY 2022 -

POWDER TESTING AND CHARACTERIZATION.. 109

An X-ray

microtomography study of packing behaviour metal powders during filling,

compaction and ball indentation process. 110

Mozhdeh Mehrabi1, Ali

Hassanpour1, Andrew Bayly1

1Dept. of Chemical and Process Engineering, University

of Leeds, Leeds, UK

Soft wheat flour

quality parameters assessment by Near Infrared Spectroscopy: from laboratory to

shelf 111

Giuseppe Bonifazi1,2*,

Riccardo Gasbarrone1, Silvia Serranti1,2

1Department of Chemical Engineering, Materials &

Environment, Sapienza University of Rome, Rome, Italy.

2Research Center for Biophotonics, Sapienza University

of Rome, Latina, Italy.

Bulk solids on the

Moon - Characterization of the innovative Lunar Regolith Simulants TUBS-M,

TUBS-T and TUBS-I. 112

Lisa Windisch1, Stefan

Linke2, Arno Kwade3, Enrico Stoll4, Carsten

Schilde5

1,3,5Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

2,4Chair of Space Technology, TU Berlin, Berlin, Germany

Effect of moisture

content, size distributions and particle shape on flowability: angle of repose,

tilting angle, and Hausner ratio. 113

Haim Kalman

Aaron Fish Chair in Mechanical Engineering – Fracture

Mechanics, The Laboratory for Conveying and Handling of Particulate Solids,

Department of Mechanical Engineering, Ben-Gurion University of the Negev, Beer

Sheva 84105, Israel.

An investigation

into the effect of drying on the flowability of the bulk pulverised cassava

grits. 114

Hamed J. Sarnavi1,

Marcelo Precoppe1, Hamid Salehi2,3, Michael S.A. Bradley3,

Pablo García-Triñanes2

1 Natural Resources Institute, University of Greenwich,

Chatham Maritime, UK

2 Materials and Chemical Engineering Group, University

of Greenwich, Chatham Maritime, UK

3 Wolfson Centre for Bulk Solids Handling Technology,

University of Greenwich, Chatham Maritime, UK

Moisture caking:

Accelerated caking tests. 115

Jairo Paternina, David Craig, Mason

Parker

Jenike & Joahnson,

Inc. (Tyngsboro, Massachusetts, USA)

A novel method

developed to measure tensile strength of cohesive powders. 116

Vivek Garg, Tong Deng, Richard Farnish, Mike Bradley

The Wolfson Centre for

Bulk Solids Handling Technology, School of Engineering, Faculty of Engineering

& Science, University of Greenwich, Central Avenue, Chatham, Kent, ME4 4TB,

UK

Influence of

particle size and void fraction on evaluation of flowability and cohesiveness

of a test of powder discharge by air pressure. 117

Koichiro Ogata1, Daigo Ariga2, Shunta

Tsukuma2, Yuuma Hirose2

1Dept. of Mechanical Engineering, National Institute of

Technology, Oita College, Oita, Japan

2 Dept. of Mechanical

and Environmental System Engineering, National Institute of Technology, Oita

College, Oita, Japan

Comparison of

low-stress flowability measurement techniques: ball indentation and shear cell 118

Azza Aly-Mahmoud1,2 ,

Colin Hare1,3 , Chuan-Yu Wu 1 , Ali Hassanpour4

1 Chemical and Process Engineering, University of

Surrey, Guildford, UK

2 Physics department, Alexandria University,

Alexandria, Egypt

3 School of Engineering, Newcastle University,

Newcastle upon Tyne, UK

4 School of Chemical and Process Engineering,

University of Leeds, Leeds, UK

Measurement of

particle contact area using a mechanical surface energy tester and influences

of surface texture of powders on particle adhesion. 119

Vivek Garg, Tong Deng, Richard

Farnish, Mike Bradley

The Wolfson Centre for

Bulk Solids Handling Technology, School of Engineering, Faculty of Engineering

& Science, University of Greenwich, Central Avenue, Chatham, Kent, ME4 4TB,

UK

Flowability and

granular compaction from industrial powders to frontier science seeking for the

missing key. 120

Maria-Graciela Cares1 ,

Maria-Camila Jimenez1,2, Andrea SuazaMontalvo1 ,Véronique

Falk1

1 LRGP-CNRS, Université de Lorraine, Nancy, France

2 Dep. of Process Engineering, INRS,

Vandœuvre-lès-Nancy, France)

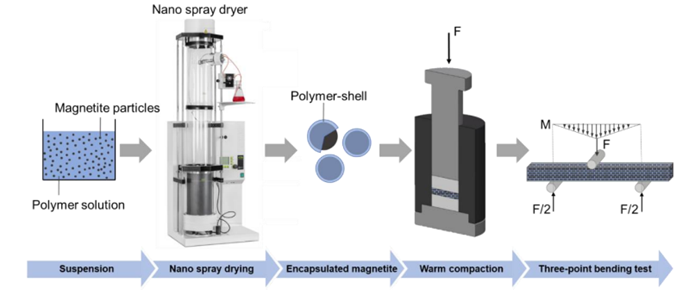

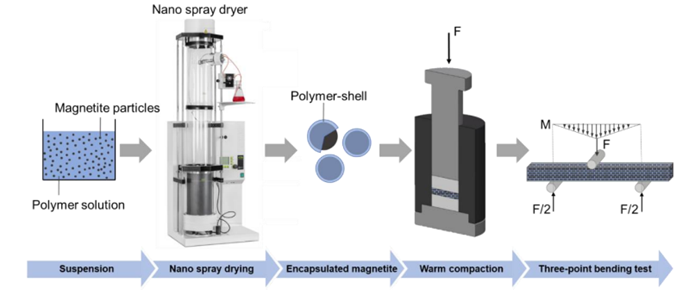

Production of

composite materials from spray drying and warm compaction. 121

Sophia Rothberg, Swantje

Pietsch-Braune, Stefan Heinrich

Institute of Solids

Process Engineering and Particle Technology, Hamburg University of Technology,

Hamburg, Germany

The Virtual

Formulation Laboratory: a novel means to facilitate smooth transition of new

powder formulations across the divide between formulation development and

manufacturing. 122

M Bradley, C Sinka, M Ghadiri, J Heng

Universities of Greenwich,

Leicester, Leeds and Imperial

Predicting turbulent

shear stress in pharmaceutical vessels. 123

Róisín Hurley1, Patrick

Frawley2

1Dept. of Mechanical Engineering, University of

Limerick, Limerick, Ireland

2Dept. of Aeronautical Engineering, University of

Limerick, Limerick, Ireland

A regime map for dry

powder coating. 124

Marv Khala1, Colin

Hare2, Vikram Karde3 and Jerry Heng3

1Dept. of Chemical & Process Engineering,

University of Surrey, Guildford, UK

2School of Engineering, Newcastle University, Newcastle

upon Tyne, UK

3Dept. of Chemical Engineering, Imperial College

London, London, UK

Investigating

particle properties and process parameters for generating efficient dry

particle coated system.. 125

Vikram Karde1 , Marv J.

Khala2,3 , Colin Hare3 , Jerry Y. Y. Heng1,4

1Department of Chemical Engineering, Imperial College

London, London, U.K.

2Department of Chemical and Process Engineering,

University of Surrey, Guildford, U.K. 3School of Engineering,

Newcastle University, Newcastle, U.K.

4Institute of Molecular Science and Engineering,

Imperial College London, London, U.K.

Water storing bulk granular

materials for concrete 3D printing. 126

Leigh Duncan Hamilton1 ,

Sandra Breitung-Faes2 , Arno Kwade3

1,2,3Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

Key words: Additive

manufacturing, water storage, dry water, granular material, flowability

Development of

hyperspectral imaging classification model applied to the recognition and

sorting of post-earthquakeconstruction waste. 127

G. Bonifazi1, O. Trotta1,

G. Capobianco1, S. Serranti1

1Department of Chemical Engineering, Materials &

Environment, Sapienza – University of Rome, Via Eudossiana, 18, 00184 Roma,

Italy

2Research

Center for Biophotonics, Sapienza University of Rome, Latina, Italy.

FRIDAY, 8 JULY 2022 -

COMPUTATIONAL MODELS. 128

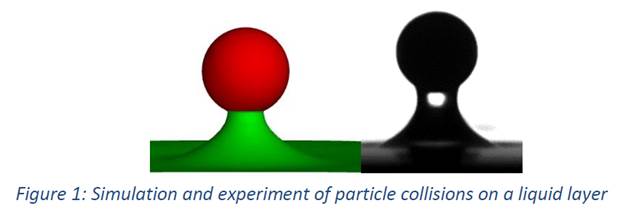

Resolved simulation

of particle collisions on wet microstructured surfaces. 129

David Strohner1 , Sergiy

Antonyuk1

1Technische Universität Kaiserslautern, Institute of

Particle Process Engineering, Kaiserslautern, Germany

Development and

application of BPM-DEM to study mechanics of frozen granular materials. 130

Tsz Tung Chan1 , Jürgen

Grabe2 , Stefan Heinrich1 , Maksym Dosta1

1 Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology (TUHH), Hamburg, Germany

2 Institute of Geotechnical Engineering and

Construction Management, Hamburg University of Technology (TUHH), Hamburg,

Germany

Multi-Scale and

Multi-Physics Modelling of particle and fluid-particle flow using DEM and

CFD-DEM... 131

Christoph Goniva1,

Riccardo Togni1, Marcel Kwakkel1 and Christoph Kloss1

1DCS Computing GmbH, Linz, Austria

Tensor-based coarse

graining method. 132

Zorica Ristic1, 2 , Arno

Mayrhofer2 , Stefan Radl1

1 Institute of Process and

Particle Engineering, Graz University of Technology, Graz, Austria

2 DCS Computing GmbH, Linz, Austria

On the use of

coarse-graining to bridge the discrete and continuum descriptions of granular

materials. 133

Hongyang Cheng1,

Stefan Luding2, Thomas Weinhart2

1Department of Civil Engineering, Faculty of

Engineering Technology, MESA+, University of Twente, P.O. Box 217, 7500 AE

Enschede, The Netherlands

2Multi-Scale Mechanics (MSM), Faculty of Engineering

Technology, MESA+, University of Twente, P.O. Box 217, 7500 AE Enschede, The

Netherlands

Modelling hopper

discharge of elongated particles with different shape representation methods. 134

Marina Sousani1,

Stefanos-Aldo Papanicolopulos2, Andreas Piskopakis1,

Timothy Heelis1

1EDEM, Altair Engineering Ltd, Edinburgh, United

Kingdom

2School of Engineering, Institute for Infrastructure

and Environment, The University of Edinburgh, Edinburgh, United Kingdom

Effect of

coarse-grain scaling in Discrete Element Method (DEM-CFD) modelling of CFB

riser reactors. 135

Erasmo S. Napolitano1 ,

Alberto Di Renzo1 , Francesco P. Di Maio1

1 DIMES Department, Università della Calabria, Rende (CS),

Italy

MercuryDPM: Fast,

flexible, particle simulations. 136

Anthony R Thornton1,2,

Thomas Weinhart1,2, et al.3

1Thermal and Fluid Engineering (ET), University of

Twente, Drienerlolaan 5, 7500 AE Enschede, The Netherlands

2MercuryLab, Mekkelholtsweg 10, 7523 DE Enschede, The

Netherlands.

3A full list of contributors can be found here:

https://www.mercurydpm.org/about-this-code/team

Triaxial testing for

granular materials using the Discrete Element Method. 137

John P. Morrissey1 ,

Stefan Pantaleev1,2 , Jin Y. Ooi1

1 School of Engineering, University of Edinburgh,

Edinburgh, UK.

2 Altair EDEM, Edinburgh, UK

Coupling of DEM and

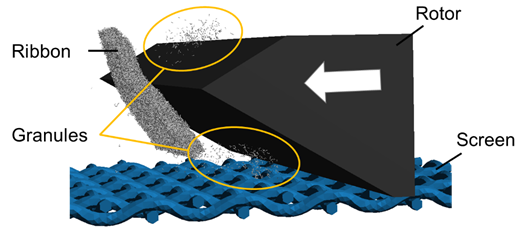

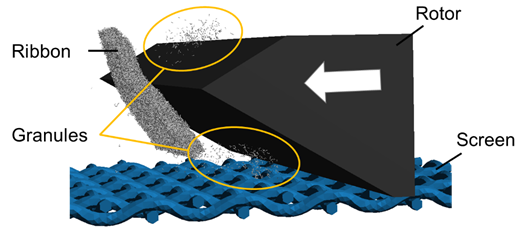

flowsheet simulations for screen mills in roller compaction process. 138

Christian Eichler, Maksym Dosta,

Stefan Heinrich

Institute of Solids

Process Engineering and Particle Technology, Hamburg University of Technology,

Hamburg, Germany

Benchmark of

different discrete particle models for the simulation of pneumatic conveying of

additive manufacturing metallic powders. 139

Lorenzo Pedrolli1*,

Alejandro López1, Inger Martinez de Arenaza1, Beatriz

Achiaga Menor1

1Dept. of Mechanics, Design and Industrial

Organization, University of Deusto, Bilbao, Spain

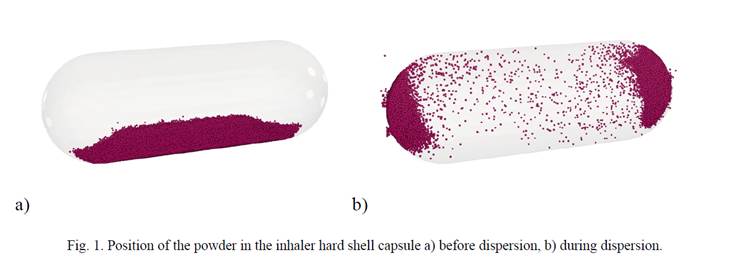

Analysis of

micron-sized particle emission from the capsule of a Dry Powder Inhaler through

DEM simulations. 140

Francesca Orsola Alfano1,

Alberto Di Renzo1, Francesco Paolo Di Maio1, Martin

Sommerfeld2

1 DIMES Department, University of Calabria, Cosenza,

Italy

2 Fakultät für Verfahrens- und Systemtechnik, Otto von

Guericke University, Magdeburg, Germany

Wear deformation

prediction of convex pattern surface using DEM... 141

Yunpeng Yan1, Rudy Helmons1,2

Craig Wheeler3, Michael Carr3,

Dingena Schott1

1 Department of Maritime and Transport Technology, Delft

University of Technology, 2628 CD Delft, The

Netherlands

2 Department of Mineral Processing and HSE, Norwegian

University of Science and Technology, 7031 Trondheim, Norway

3 School of Engineering, The University of Newcastle,

Callaghan 2308, Australia

FRIDAY, 8 JULY 2022 -

INDUSTRIAL CASE STUDIES. 142

Improving a pneumatic

conveying system for coffee beans to reduce attrition. 143

Harald Wilms1, Sebastian

Husheer2

1Wilms-ITC, Innovation-Technology-Consulting, Bremen,

Germany

2Jacobs Douwe Egberts DE GmbH, Bremen, Germany

Leveraging

Artificial Intelligence to speed up DEM simulations: A wheel loader case study. 144

Spyridon Mallios, Marina

Sousani, Livio Mariano

Altair Engineering, Troy,

Michigan, United States

Innovations in

particle technology modelling to improve industrial product development 145

Stefan Bellinghausen1,

Dana Barrasso2, Sean K. Bermingham1

1 Siemens Process Systems Enterprise Ltd., London, UK

2 Siemens Process Systems Enterprise Inc., Parsippany,

NJ, USA

The application of

multi screw feeders to avoid flow problems: Sometimes one screw is not enough! 146

Eddie McGee1

1 Managing Director, Ajax Equipment Ltd, Milton Works,

Mule Street, Bolton BL2 2AR, UK

Improved processing in

extrusion by BASF. 147

Rou Hua, Chua1*, Edward,

Bohres1, Xue, Liu2, Alexej, Michailovski1 ,

Maik, Nowak1 , Frank, Runge1 , Martin, Kraus1

, Frank, Kleine Jäger1

1BASF SE, Ludwigshafen, Germany

2BASF Corporation, Beachwood, United States

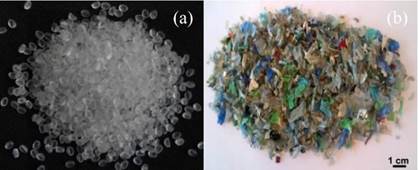

Examples for

handling of post-consumer plastic waste. 148

Harald Wilms1

1Wilms-ITC, Innovation-Technology-Consulting. Bremen,

Germany

Estimation of the

temporal variations of the feed of a sinterization process aided by a

voxelization-based numerical approach. 149

Horacio Andrés Petit1,

Luis Marcelo Tavares1

1Department of Metallurgical and Materials Engineering,

Universidade Federal do Rio de Janeiro – COPPE/UFRJ, Cx. Postal 68505, CEP

21941-972, Rio de Janeiro, RJ, Brazil

Modeling of

stockpile drainage and seepage in real applications. 150

Jairo Paternina1,

Francisco Cabrejos2, David Craig1, Rogerio Ruiz3,

Corin Holmes4, Enes Kaya4

1Jenike & Johanson, Tyngsboro, Massachusetts, USA

2Jenike & Johanson, Viña del Mar, Chile

3Jenike & Johanson, Vinhedo, Brasil

4Jenike & Johanson, Belmont, WA, Australia

FRIDAY, 8 JULY 2022 -

MIXING AND SEGREGATION.. 151

Description of size

segregation in multicomponent mixtures using a probabilistic continuum model 152

Monica Tirapelle1, Silvia

Volpato1 , Andrea C. Santomaso1

1Dept. of Industrial Engineering, University of Padova,

Padova, Italy)

Solid state material

driven turbine to reduce segregation effects in bunkers. 153

Michael Denzel1, Michael

Prenner1

1Chair of Mining Engineering and Mineral Economics –

Conveying Technology and Design Methods, University of Leoben, Leoben, Austria

The development of

new radial stress theory to predict segregation: The relationship between mass

flow, segregation prevention, and stress and gas pressure gradients. 154

Kerry Johanson1

1Material Flow Solutions, Gainesville FL, USA

Batch versus

continuous powder mixing of excipients and active pharmaceutical ingredients. 155

Maarten Jaspers1,

Pauline H.M. Janssen1, Bastiaan H.J. Dickhoff1

1Dept. of Innovation and Technical Solutions, DFE

Pharma GmbH & Co, Goch, Germany

Advantages of a

continuous measurement of great mass flows in a mixing process for cement plant

application using an electromagnetic + time of flight online massflow meter. 156

Tiago Morais1, Philipp

Tretow1, Lars Orzelkiewicz1, Gilles Campagnola2,

Alexandra Schmedt1

1ENVEA Process SchlingenGermany

2 ENVEA Spa Verano Brianza Italy

FRIDAY, 8 JULY 2022 -

COMPACTION AND TABLETING.. 157

Modeling the shear

sensitivity of lubricated powders in a paddle feeder. 158

Daniel Puckhaber1,2, Arno

Kwade1,2, Jan Henrik Finke1,2

1Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

2Center for Pharmaceutical Engineering (PVZ), TU

Braunschweig, Braunschweig, Germany

Processing of living

microorganisms: Fluidized-bed granulation and tableting. 159

Karl Vorländer1,2, Arno Kwade1,2, Jan Henrik

Finke1,2, Ingo Kampen1,2

1Institute for Particle Technology, Technische

Universität Braunschweig, Braunschweig, Germany

2Center of Pharmaceutical Engineering (PVZ), Technische

Universität Braunschweig, Braunschweig, Germany

Material and Process

Analyses for the Derivation of Process and Property Models in Food Compaction. 160

René Rösemeier-Scheumann1,2,

Jan Henrik Finke1,2, Ulrich Bobe3, Annabel Bozon3,

Arno Kwade1,2

1Institute for Particle Technology (iPAT), TU

Braunschweig, Brunswick, Germany

2Center of Pharmaceutical Engineering (PVZ), TU

Braunschweig, Brunswick, Germany

3Department of Science & Technology, Nestlé Product

Technology Centre, Singen, Germany

Modeling of

high-density compaction of pharmaceutical tablets using Multi-Contact Discrete Element Method. 161

Kostas Giannis 1,2,*, Carsten Schilde 1,2, Jan Henrik Finke 1,2 and

Arno Kwade 1,2

1Center of Pharmaceutical Engineering (PVZ), Technische

Universität Braunschweig, Franz-Liszt-Str. 35A, 38106 Braunschweig, Germany

2Institute for Particle Technology (iPAT), Technische

Universität Braunschweig, Volkmaroder Str. 5, 38104 Braunschweig, Germany

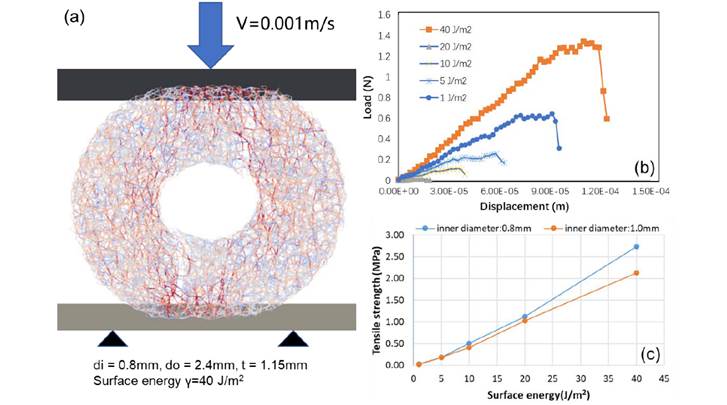

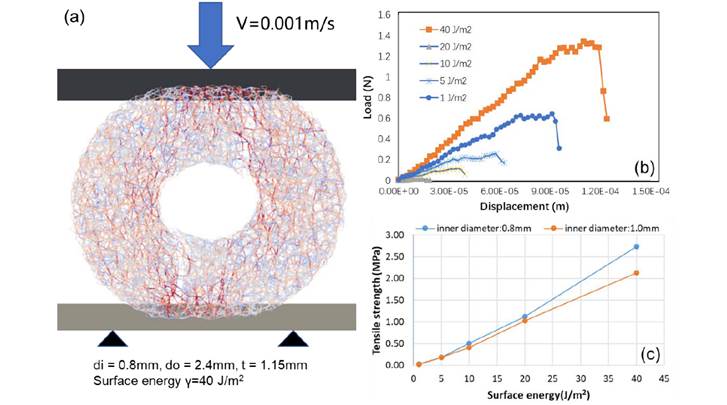

Three-dimensional

discrete element modelling of diametrical compression of annular tablet 162

Jiawei Hu, Chuan-Yu Wu*

Department of Chemical and

Process Engineering, University of Surrey, Guildford, U.K.

Material-independent

description of die filling in rotary tablet presses. 163

Ann Kathrin Schomberg1,2,

Jan Henrik Finke1,2, Arno Kwade1,2

1Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

2Center for Pharmaceutical Engineering (PVZ), TU

Braunschweig, Braunschweig, Germany

The effect of

particle adhesion on die filling performance in a gravity filling device. 164

Mohammadreza Alizadeh Behjani1,

Chao Zheng1, Omar M Ismail1, Edward Yost2,

Ariel Muliadi2, Chuan-Yu Wu 1

1School of Chemical and Process Engineering, University

of Surrey, Guildford, UK

2Small Molecule Pharmaceutical Sciences, Genentech,

South San Francisco, USA

The protective

potential of cushioning coatings on enteric-coated pellets during tableting. 165

Lara Stein1,2,3, Sonja

Bauhuber3, Gernot Warnke3, Jan Henrik Finke1,2

1Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

2Center of Pharmaceutical Engineering, TU Braunschweig,

Germany

3JRS PHARMA GmbH & Co. KG, Rosenberg, Germany

FRIDAY, 8 JULY 2022 -

AGGLOMERATION AND GRANULATION.. 166

Novel approach for

the characterization of powder caking. 167

Alessandra Hausmann1,

Britta Buck2, Lukas Blesinger2, Frank Kleine Jäger2,

Daryl Williams3

1Department for Materials, Imperial College London,

London, UK

2BASF SE, Ludwigshafen, Germany

3Department for Chemical Engineering, Imperial College

London, London, UK

Pellet screenings

sintering. 168

Helio Pereira1, Phillipe

Rocha2, Antonio Peres3

1 Iron Ore Agglomeration, Sintering and Pelletizing

Consultant, Belo Horizonte, Brazil

2 Technical Marketing Specialist, Anglo American,

Singapore, Singapore

3 Dept. of Metallurgical and Materials Engineering,

Federal University of Minas Gerais, Belo Horizonte, Brazil

Parametric study of

residence time distributions and granulation kinetics as a basis for process

modeling of twin-screw wet granulation. 169

Timo Plath1*, Carolin

Korte2, Rakulan Sivanesapillai2, Thomas Weinhart1

1 Multi-Scale Mechanics, TFE, ET, MESA+, University of

Twente, P.O. Box 217, 7500 AE Enschede, The Netherlands

2 Process

Technology Development, Engineering & Technology, Bayer AG, 51368

Leverkusen, Germany

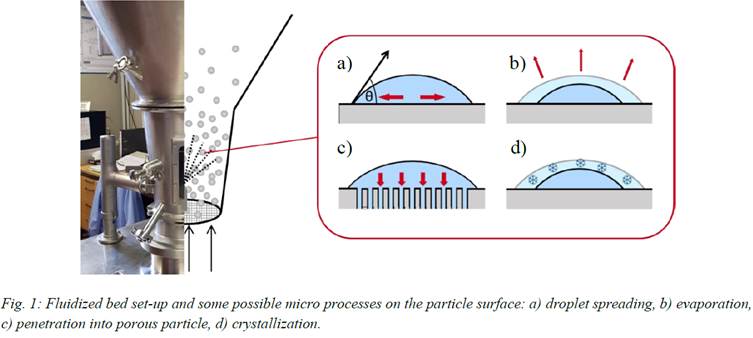

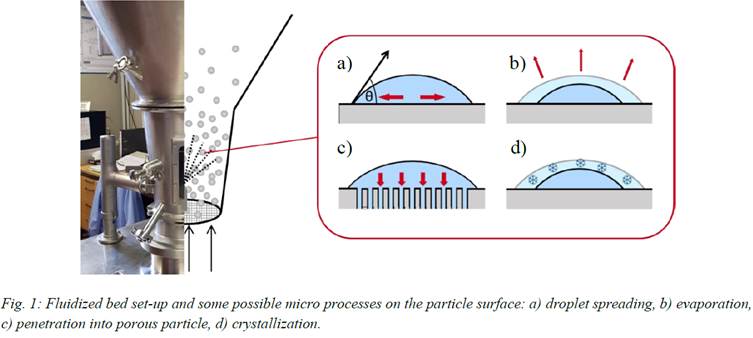

Influence of spray

configuration and material on particle formulation in fluidized beds with

liquid injection. 170

Maike Orth1, Swantje

Pietsch-Braune1, Stefan Heinrich1

1 Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology, Hamburg, Germany

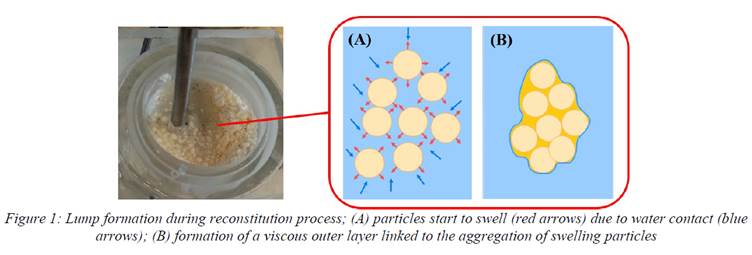

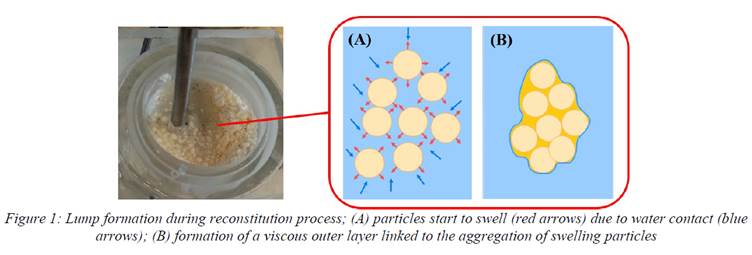

Structuration of

plant-based milk powder for improved reconstitution. 171

Kathrin Kramm1, Jana

Kammerhofer2, Vincent Meunier3, Swantje Pietsch-Braune1,

Stefan Heinrich1

1Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology, Hamburg, Germany

2Nestlé Product Technology Center Dairy, Konolfingen,

Switzerland

3Nestlé Research, Lausanne, Switzerland

FRIDAY, 8 JULY 2022 -

THERMOMECHANICAL BEHAVIOUR OF GRANULAR MATERIALS. 172

Powder flow and heat

transfer in a rotary kiln with baffles. 173

Benjamin Glasser1,

Elaheh Ardalani2, William Borghard1, Alberto Cuitino2

1Dept. of Chemical and Biochemical Engineering, Rutgers

University, Piscataway NJ, USA

2Dept. of Mechanical and Aerospace Engineering, Rutgers

University, Piscataway NJ, USA

Hot or cool; powder

characterization in non-ambient conditions – high- and low-temperature ring

shear testing. 174

Denis Schütz1, Helena

Weingrill1

1R&D Rheology (Anton Paar Gmbh, Graz Austria)

Influence of

temperature on the packing dynamics of powders. 175

Aurélien Neveu1, Geoffroy

Lumay2, Filip Francqui1

1Granutools SPRL, Awans, Belgium

2GRASP laboratory, CESAM research center, University of

Liege, Liege, Belgium

The effect of

temperature on the flow properties of SiC powders. 176

Pablo García-Triñanes1,2,

Diego Barletta3, Massimo Poletto3

1Materials and Chemical Engineering Group, School of

Engineering and the Built Environment, University of Greenwich, Chatham

Maritime, UK

2Wolfson Centre for Bulk Solids Handling Technology,

School of Engineering and the Built Environment, University of Greenwich,

Chatham Maritime, UK

3Dipartimento di Ingegneria Industriale, Università degli

Studi di Salerno, Via Giovanni Paolo II, 132, 84084 Fisciano (SA), Italy

DEM simulation

study: the effect of temperature on powder spreading in selective laser

sintering. 177

Sina Zinatlou Ajabshir1,2*,

Colin Hare2, Diego Barletta1, Daniele Sofia1,

Massimo Poletto1

1Dipartimento di Ingegneria Industriale, Università degli

Studi di Salerno, Fisciano SA, Italy

2 School of Engineering, Newcastle University,

Newcastle upon Tyne NE1 7RU, United Kingdom

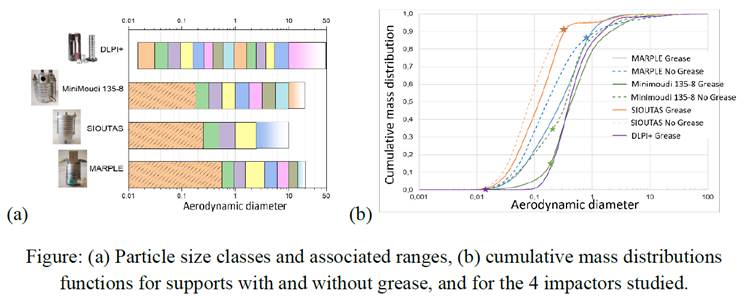

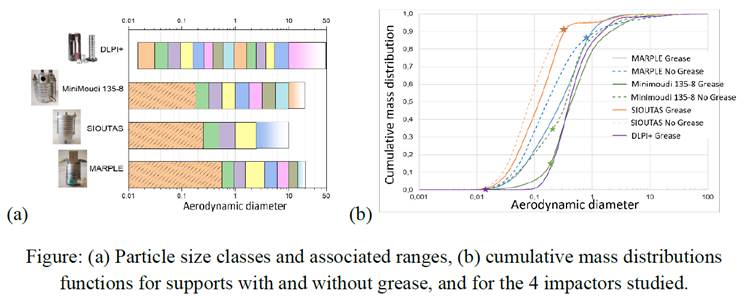

FRIDAY, 8 JULY 2022 - DUST

AND AEROSOL EMISSIONS. 178

Optimization of a

sampling method of airborne metallic ultrafine particles by cascade impactors. 179

Virginie Matera1, Naïma

Gaudel1, Sébastien Bau1

1Dept. of Pollutants Metrology, INRS (French National

Institute of Research and Safety), Vandoeuvrelès-Nancy, France

Novel technique for

economic and continuous analysis of dust exposure levels in real-life

production. 181

Michael Pilz1, Britta Buck1,

Jens Dittmann1, Rainer Friehmelt1, Frank Kleine Jäger1

1BASF SE, Ludwigshafen, Germany

Impact of powders

flowability improvement on their dustiness generation. 182

Maria-Camila Jiménez-Garavito1,2,

Maria-Graciela Cares-Pacheco2, Fabien Gerardin1,

Véronique Falk2

1Institut national de recherche et de sécurité, 54519,

Vandœuvre-lès-Nancy, France

2Laboratoire de Réactions et Génie des Procédés, 54000,

Nancy, France

SATURDAY, 9 JULY 2022 - FROM

PARTICLE CONTACTS TO BULK BEHAVIOUR.. 183

Modeling snow

deformation: from a meso grain to bulk behavior. 184

Mohammed Hassan1, Eelco

Verhulp 2, Vanessa Magnanimo3, Stefan Luding4

1MSM-ET-TFE, University of Twente, Enschede,

Netherlands

2Apollo Tyres Global R&D B.V., Enschede,

Netherlands

3CME -ET, University of Twente, Enschede, Netherlands

4MSM-ET- TFE, University of Twente, Enschede,

Netherlands

A Study on the

charge neutralising effect of Aluminium Stearate in triboelectrification. 185

Jiachen Guo1,2, Wei Pin

Goh1, Mojtaba Ghadiri1

1School of Chemical and Process Engineering, University

of Leeds, Leeds, UK

2College of Civil Aviation, Nanjing University of

Aeronautics & Astronautics, Nanjing, China

Adhesive

particle-particle contact and how it affects ceramic's bulk flow behaviour. 186

Zohreh Farmani1, Joshua.A.

Dijksman1

1Dept. of Physical Chemistry and Soft Matter,

University of Wageningen, Wageningen, The Netherlands

From particles to

continuum: Review of micro-macro approaches. 187

Stefan Luding1

1Multi-Scale Mechanics (MSM), Department Thermal and

Fluid Engineering (TFE), Faculty of Engineering Technology (ET), MESA+, POBox

217, 7500AE Enschede, NL

Implementation and

Calibration of a Viscoelastic Bonded-Particle model: comparison of Burgers and

Generalized Maxwell Relations and their flow prediction ability. 188

Michael Mascara1,2, Arno

Mayrhofer1, Stefan Radl2, Christoph Kloss1

1 DCS Computing GmbH, Industriezeile 35a, 4020 Linz,

Austria

2 TU Graz, Institute of Process and Particle

Engineering, Inffeldgasse 13/III, 8010 Graz, Austria

Concrete parts from

the powder bed – Material modification for selective cement activation. 189

Niklas Meier1, Harald

Zetzener1, Arno Kwade1

1Institute for Particle Technology, TU Braunschweig,

Braunschweig, Germany

Keywords: concrete, powder

bed, 3D-printing, SCA, flowability, porosity

Prediction of bulk

flow properties using mechanical surface energy tester. 190

Vivek Garg, Tong Deng, Richard

Farnish, Mike Bradley

The Wolfson Centre for

Bulk Solids Handling Technology, School of Engineering, Faculty of Engineering

& Science, University of Greenwich, Central Avenue, Chatham, Kent, ME4 4TB,

UK

SATURDAY, 9 JULY 2022 - ADDITIVE MANUFACTURING AND

POWDER SINTERING.. 191

Surface tailored

metal particles for additive manufacturing. 192

Arne Lüddecke1, Harald

Zetzener1, Jan Sehrt2, Arno Kwade1

1Institute for Particle Technology, Technische

Universität Braunschweig, Germany

2Hybrid Additive Manufacturing, Ruhr-Universität Bochum,

Bochum, Germany

Keywords: Additive

manufacturing, PBF-LB/M, Powder flowability, Nanoparticles

Material properties

and process parameter optimization in Selective Laser Sintering of polymers. 193

Federico Lupone1, Elisa

Padovano1, Francesco Casamento1, Claudio Badini1

1Dept. of Applied Science and Technology (DISAT),

Polytechnic of Turin, Turin, Italy

Fluidized bed

machining of AlSi10Mg samples produced by additive manufacturing. 194

Maurizio Troiano1, Andrea

El Hassanin1, Alessia Teresa Silvestri1,2, Fabio

Scherillo1, Fabrizio Scala1, Roberto Solimene3*,

Antonino Squillace1, Piero Salatino1 194

1Dipartimento di Ingegneria Chimica, dei Materiali e della

Produzione Industriale, Università degli Studi di Napoli Federico II, Napoli,

Italy

2Dipartimento di Ingegneria Gestionale, dell'Informazione e

della Produzione, Università degli Studi di Bergamo, Bergamo, Italy

3Istituto di Scienze e Tecnologie per l'Energia e la Mobilità

Sostenibili, Consiglio Nazionale delle Ricerche, Napoli, Italy

Quantitative

analysis of the powder layer quality in the Selective Laser Sintering process:

Experiments and DEM modelling. 195

Marco Lupo1, Daniele Sofia1,2,

Diego Barletta1, Massimo Poletto1

1Dept. of Chemical Engineering, University of Salerno,

Salerno, Italy

2Sense square Srl, Salerno, Italy

Spreadability versus

flowability: Transient jamming makes them different 196

Wei Pin Goh1, Wenguang Nan1,2,

Mehrdad Pasha1,3, Mojtaba Ghadiri1

1School of Chemical and Process Engineering, University

of Leeds, Leeds, UK

2School of Mechanical and Power Engineering, Nanjing

Tech University, Nanjing 211816, China

3UCB Pharma, Chemin du Foriest B-1420 Braine l'Alleud,

Belgium

Modelling of selective laser sintering

of visco-elastic powders. 197

Juan E. Alvareza, Bert Nijkampa,

Hongyang Chenga,b, Stefan Ludinga, Thomas Weinharta

aMulti-scale Mechanics, University of Twente, The Netherlands.

bDepartment of Civil Engineering, University of Twente, The

Netherlands.

A comparative study

on polymeric materials for the selective laser sintering process. 198

Daniele Sofia1,2, Diego

Barletta1, Massimo Poletto1

1Dept. of Chemical Engineering, University of Salerno,

Salerno, Italy

2Sense square Srl, Salerno, Italy

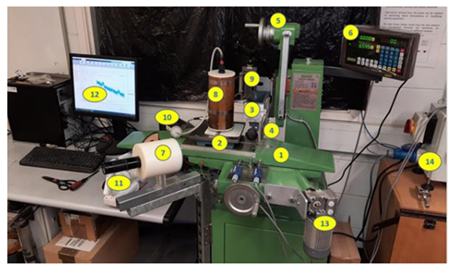

A new approach to quantify

powder's bed surface roughness in additive manufacturing. 199

Hamid Salehi1, 2, John

Cummins1, Enrico Gallino3, Neil Harrison4, Ali Hassanpour5 and

Mike Bradley1

1Wolfson Centre for Bulk Solids Handling Technology,

University of Greenwich, Chatham, UK

2School of Engineering, University of Greenwich,

Chatham, UK

3RICOH UK Products Ltd, Priorslee, Telford, UK

4Carpenter Additive, Widnes, UK

5School of Chemical and Process Engineering, University

of Leeds, Leeds, UK

SATURDAY, 9 JULY 2022 -

PARTICLE DEFORMATION.. 200

Particle-wall

collision characteristics for non-spherical particles under normal impact:

Numerical investigation. 201

Rahul Tarodiya, Avi Levy

Dept. of Mechanical

Engineering, Ben-Gurion University of the Negev, Beer-Sheva, Israel

Discrete Element

Modeling of strongly deformed particles in dense shear flows. 202

Nazanin Ghods1, Payam Poorsolhjouy2,

Marcial Gonzalez3,4, Stefan Radl1

1 Institute of Process and Particle

Engineering, Graz University of Technology, Inffeldgasse 13/III, 8010, Graz,

Austria

2 Department of the Built Environment, Eindhoven

University of Technology, 5612 AZ Eindhoven, Netherlands

3 School of Mechanical Engineering, Purdue University,

West Lafayette, IN 47907, USA

4 Ray W. Herrick Laboratories, Purdue University, West

Lafayette, IN 47907, USA

Water content

related changes on wood pellet properties. 203

Abdullah Sadeq1, Swantje

Pietsch1, Maksym Dosta1, Stefan Heinrich1

1Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology, Hamburg, Germany

Understanding

structured particle breakage using population balance modeling coupled with FEM

calculation and phase-field model (PFM) prediction of crack propagation. 204

Kerry Johanson1

1Material Flow Solutions, Gainesville FL, USA

Modelling of surface

erosion for polymers and polymer composites due to solid particle impact 205

Rahul Tarodiya, Avi Levy

Dept. of Mechanical

Engineering, Ben-Gurion University of the Negev, Beer-Sheva, Israel

Modelling particle

breakage using a bonded particle model 206

John P. Morrissey1 ,

Xizhong Chen2 , Li Ge Wang3 , Jin Y. Ooi1

1 School of Engineering,

University of Edinburgh, Edinburgh, UK.

2 Department of Chemical

and Biological Engineering, University of Sheffield, Sheffield, UK 3 Process

Systems Enterprise, Hammersmith, London, United Kingdom

Numerical

investigation of hydro-abrasive erosion of Pelton turbine injector. 207

Rahul Tarodiya1, Subodh

Khullar2, Avi Levy1

1Dept. of Mechanical Engineering, Ben-Gurion University

of the Negev, Beer-Sheva, Israel

2Dept. of Mechanical and Industrial Engineering, IIT

Roorkee, Roorkee, India

Simulation of

surface abrasion in DEM... 208

R. Capozza and K. J. Hanley

School of Engineering,

Institute for Infrastructure and Environment The University of Edinburgh,

Edinburgh EH9 3JL, UK

POSTERS. 209

A numerical

assessment of different bend geometries for reducing erosion during pneumatic

conveying. 210

Eric Drescher1, Shoya

Mohseni-Mofidi2, Claas Bierwisch2, Harald KruggelEmden1

1Chair of Mechanical Process Engineering and Solids

Processing, Technische Universität Berlin, Berlin, Germany

2Fraunhofer Institute for Mechanics of Materials IWM,

Freiburg, Germany

Pneumatic handling

of bio and recycled solids (PHOBARS project) 211

Manuela Quezada Henry1, Mikel Leturia1, Elias

Daouk1, Thierry Destoop2, Fabrice Bonny2,

Antoine Flament2, Mathieu Morin3, Sina Tebianian3,

Khashayar Saleh1

1Université de Technologie de Compiègne, ESCOM, TIMR

(Integrated Transformations of Renewable Matter), Centre de recherche de

Royallieu, Compiègne, France

2NEU-JKF Process, La Chapelle d'Armentières, France

3IFP Energies Nouvelles, Solaize, France

Impact of powder and

tableting parameters on tablet properties. 212

Amine Ait Ouazzou1, Yogesh

Harshe2, Vincent Meunier3, Stefan Heinrich4

1,4Institute of Solids Process Engineering and Particle

Technology, Hamburg University of Technology, Hamburg, Germany

2,3Nestlé Research, Route du Jorat 57, CH 1000 Lausanne,

Switzerland

Experimental investigation

on the role of particle shape and cohesion in the bulk flow behaviour of glass

particles in a rotating drum.. 213

Wei Pin Goh, Mojtaba Ghadiri

School of Chemical and

Process Engineering, University of Leeds, Leeds, UK

Preliminary

investigation of fluidized bed reactors for carbon dioxide methanation by TPSIM

Win software. 214

Cesare Saccani, Marco Pellegrini,

Alessandro Guzzini

Department of Industrial

Engineering (DIN), University of Bologna, Bologna, Italy

Investigation of the

agglomeration of particulate matter in chimneys using acoustic flow.. 215

Kristina Kilikevičienė1*,

Rimantas Kačianauskas1, Vytautas Rimša2, Artūras Kilikevičius1

1 Institute of Mechanical Science, Vilnius Gediminas

Technical University, Vilnius, Lithuania

2 Department of Aviation Technologies, Vilnius

Gediminas Technical University, Vilnius, Lithuania

Meso-scale DEM for

flowability assessment of weakly consolidated fine powders in industry. 216

Rahul Sharma1, Massimo

Poletto1, Diego Barletta1, Jin Ooi2, Stefanos Papanicolopulos2, Marina Sousani3

1Department of Industrial Engineering, University of

Salerno, Salerno, Italy

2School of Engineering, The University of Edinburgh,

Edinburgh, UK

3Altair EDEM, DEM Solutions Ltd, Edinburgh, UK

DEM (meso-)particle

property calibration with powder rheometry and other flow characterization

techniques. 217

Assem Zharbossyn1,

Diego Barletta1, Massimo Poletto1, Vanessa Magnanimo2,

Stefan Luding2, Anthony Thornton2

1Department of Industrial Engineering, University of

Salerno, Salerno, Italy

2Multi Scale Mechanics (MSM), University of Twente,

Enschede, The Netherlands

Analysis of the

interaction of a fine particle as a droplet on a specific surface. 218

Tim Tofan1,*, Rimantas Kačianauskas2,3,

Raimondas Jasevičius1,3

1Department of Department of Mechanical and Materials

Engineering, Vilnius Gediminas Technical University, Vilnius, Lithuania

2Department of Applied Mechanics, Vilnius Gediminas

Technical University, Vilnius, Lithuania

3 Institute of Mechanical Science, Vilnius Gediminas

Technical University, Vilnius, Lithuania

PLENARIES

6 July 2022 am

Heinrich Jaeger

University of

Chicago - United States

The behavior of granular material is determined largely

by the interfaces between constituent particles. These

interfaces generate contact interactions that can be highly nonlinear and

that depend on particle size and shape as well as surface properties. Together with the inherent disorder in the

particles' configuration, this complexity poses challenges for predicting the

behavior of particulate matter. However, in recent years there have been great

strides in better understanding these interactions and controlling the

interface properties, with major impact across many different areas where

particle-particle contacts play a key role. At the same time, this has opened up new possibilities for designing granular material

with novel, desired bulk properties.

This talk will outline some of the emerging opportunities in areas

ranging from collisional contact charging to dense suspension rheology and from

jamming-based soft robotics to reconfigurable architectures.

LIST OF ABSTRACTS

AND INDEX

6 July 2022 pm

Dingena Schott

Delft University

of Technology - The Netherlands

Developments

in discrete element modelling (DEM) enable detailed modelling of granular flows

in bulk handling equipment but due to the computational expense of DEM, however

a wide use in analysing equipment performance or design optimisation procedures

is not yet feasible. Metamodels, or a model of a DEM model in this context, are

considered a viable option to effectively use DEM in analysing and improving

equipment performance by exploring a wide range of design parameter values.

In this

work we show ways of how to use DEM-based metamodeling to the benefit of

designing bulk handling equipment. Firstly, we present a methodology to

construct and validate DEM-based metamodels. Along with that we present a case

study of a discharging hopper illustrating the use and benefits of metamodels

in combination with DEM. Secondly, we demonstrate how metamodels can be applied

on an industrial scale for complex operational conditions, such as varying bulk

material states. The metamodel development

in this case is based on a full-scale DEM-MBD co-simulation of a grab that has

been used to generate the performance for various levels of bulk cohesion and

compressibility (plasticity). By creating metamodels based on these results we

could efficiently explore optimal design parameters using an optimization

approach.

LIST OF

ABSTRACTS AND INDEX

7 July 2022 am

Chuan-Yu (Charley) Wu

Department of

Chemical and Process Engineering, University of Surrey, Guildford, GU2 7XH, UK

Many Powder handling and particulate

product manufacturing processes involving deposition of bulk solids in confined

spaces of a small volume, such as filling a die or a capsule with several

hundred milligrams or a few grams of powder mixtures during manufacturing of

pharmaceutical tablets/capsules, metallurgical and ceramic parts, as well as

powder-based cosmetic products. It is crucial to consistently fill these spaces

in order to achieve the desired product quality.

However, it is an scientifically and technologically

challenging task, requiring a thorough understanding of powder flow behaviours

in these processes. This talk aims to discuss the challenges in depositing

small quantities of powders into a confined space, to explore the complex

powder behaviours in these processes and to evaluate how particle properties

and their interactions will affect the bulk flow behaviour. Furthermore, how to

effectively characterise powder flow properties for this application will be

discussed. The impact of electrostatics

and the presence of air on the flow behaviour will also be presented.

Keywords:

Powder flow; flowability; die filling; segregation; electrostatics, DEM-CFD.

LIST OF

ABSTRACTS AND INDEX

7 July 2022 pm

Raffaella Ocone

Heriot-Watt University, United Kingdom

Granular materials exhibit a broad range of

intricate dynamic behaviours. The study of their hydrodynamics is extremely

relevant in the chemical and process industries, where those materials are

widely produced and handled. Understanding how internal (e.g., particles size

and shape) and external (e.g., applied stresses, moisture content) physical

properties impact on the flow behaviour of solid particles helps industrial

practitioners handle and produce particulates in an efficient and less costly

way.

Powders can rearrange under stress and, as

a result, granular flow is generally classified into three flow regimes, namely

a quasi-static regime, dominated by frictional contacts, an inertial regime,

dominated by collisional and kinematic stresses, and an intermediate regime

where all three sources of stress are important to establish a stress-strain

rate relationship. Characterisation of powder flowability is gener0ally

restricted to the flow initiation in quasi-static regime, even if, transition

into inertial conditions is very common and relevant in practical applications.

The talk will present a critical review of

available techniques to characterise the departure from the quasi-static regime

into an intermediate flow. We revise the application of shear cells and, in the

effort to characterise the departure for the quasi-static regime, we explore

the challenges associated with elucidating

the rheological behaviour of aerated powders. A commercial instrument, namely

the Freeman FT4 Powder Rheometer, is modified to generate Couette flow. The

development of the modified instrument, called the “Aerated Bed Virtual Couette

Rheometer” (AB-VCR), is presented. The AB-VCR is employed in both non-aerated and aerated modes

to determine the rheology of monodispersed spherical glass beads with and

without moisture. Systematic measurements of the stresses which develop within

the granular medium are presented and a rheological law is proposed. The

validity of such a constitutive law is tested and discussed.

LIST OF

ABSTRACTS AND INDEX

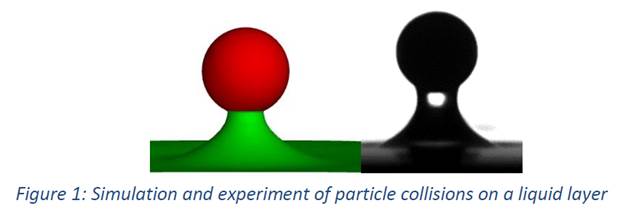

8 July 2022 am

Pierre Jop

Glass Surface and Interfaces, CNRS/Saint-Gobain, France

Blending

grains with a liquid is often the first step in an industrial process, however

it is difficult to give a global description due to the triphasic nature of the

medium: Cohesion induced by capillary bridges and the progression of liquid in

the system create boundaries between zones of different mechanical behavior.

Such spatial heterogeneities need to be erase during

mixing steps for example. While the static behavior of a homogeneous, partially

saturated media is rather well understood, the time evolution of a

heterogeneous system is less described. One key ingredient during this

presentation is the capillary forces that constrain the movement of the grains.

In this lecture, I will illustrate different situations inspired by industrial

applications in which the behavior of a granular material evolves with the amount

of liquid, relevant for mixing or aggregation topics. From very low liquid

contents to dilute suspensions, I will focus on capillaries effect through

model experiments that highlight the role of the liquid interfaces to describe

the propagation of the fluid, the morphology of the interfaces and the mechanic

of the media.

LIST OF

ABSTRACTS AND INDEX

8 July 2022 pm

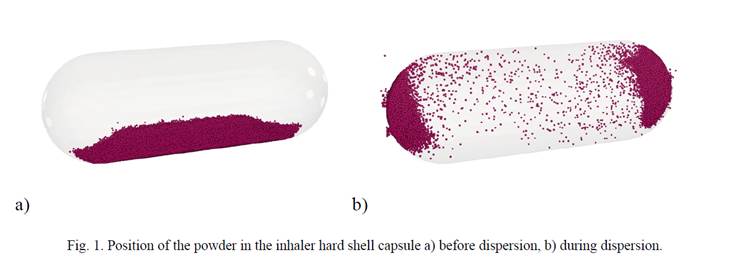

Andrea

Benassi

Chiesi Farmaceutici Spa, Parma (Italy)

Orally

inhaled drug products (OIDPs) are pharmaceutical forms involving the

entrainment of powder particles or droplets by an air stream generate by

patient breathing or by a single inspiratory act. Many aspects, in the design

of these products, require an intimate understanding of fluid and powder

behavior as well as their complex and non-linear interplay in determining the

aerosol physics. Recently, simulation tools based on computational fluid dynamics

(CFD) and discrete element modeling (DEM) have attracted a growing interest in

the OIDPs community, thanks to their explanatory and predictive capabilities.

Some recent and promising applications of CFD-DEM computational tools to

problems of aerosol generation and deposition in human lungs will be reviewed.

The characteristic numbers and orders of magnitude for the main physical

quantities will be discussed along with the available experimental techniques

we can use to characterize the phenomena and to generate data to validate the

simulations. Achievements and current limitations of the computational models

will be illustrated.

LIST OF

ABSTRACTS AND INDEX

9 July 2022 am

Jochen Schmidt1,2

1Institute of Particle Technology, Department of Chemical and

Biological Engineering, Friedrich-Alexander-Universität Erlangen-Nürnberg,

Erlangen, Germany

2Colloborative Research Center 814 “Additive Manufacturing”,

Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany

Additive

manufacturing (AM) processes allow for the production of

individualized components of complex geometries without the need for tools or

molds. If functional AM-built components of good mechanical properties are

desired, typically powder bed fusion (PBF) AM processes are employed. In case

of plastic components, PBF of polymers with laser beam (PBF/LB-P) also known as

(selective) laser sintering, is an established AM method, while in case of

additive manufacture of metal components, PBF of metals with laser beam

(PBF-M/LB) and electron beam (PBF-M/EB) are frequently used.

In the aforementioned PBF-AM processes, a powder layer is spread

onto the building platform within a heated build chamber and the contour of the

part to be produced is selectively fused by the beam source. Then, the building

platform is lowered, a new powder layer is spread and

the next cross-section of the component is fused. The process sequence is

repeated, until the build job is finished. The component quality is determined

by the interaction of the AM machine with the feedstock powder. Moreover, the

feedstock powders need to exhibit certain bulk solid characteristics, as well

as appropriate thermal and rheological properties. Concerning bulk solid properties it becomes obvious from the sketched AM process

sequence, that flowability and packing fraction, are the key towards successful

powder spreading and preparation of a powder bed of homogeneous packing density

and, thus, the reproducible manufacture of dense parts of sufficient mechanical

properties and dimensional accuracy.

Within this

contribution, powder requirements for PBF-AM processes will be addressed and established,

state-of-the-art methods as well as novel approaches for characterization of

bulk solid properties of AM feedstock powders under process conditions will be

reviewed and assessed with respect to the method's predictability of the

feedstock's AM processability. Moreover, some important plastic powder

production and functionalization methods will be briefly sketched and the

effect of particle (c.f. size distribution, shape) and bulk solid properties on

part properties and processability, i.e. structure-property relationships along

the AM process chain will be demonstrated for selected examples.

LIST OF

ABSTRACTS AND INDEX

Christine M. Hrenya

University of

Colorado - United States

An accurate and robust particle-particle

cohesion model, as is used in DEM, is notoriously challenging to obtain.

For example, the AFM measurement of particle-particle cohesion is non-trivial

at best for rough and/or non-spherical particle. In this work, we

demonstrate how an Anton-Paar rheometer is used to obtain the cohesive force

and energy for a given set of particles via bulk defluidization in the

rheometer. The resulting simple, yet physically sufficient

square-force model of cohesion is then applied to an experimental system for

measuring the angle of repose. This (different) system is a robust

validation test since it is shown to involve both force-dominated and energy-dominated

contacts (enduring contacts and brief collisions, respectively). The DEM

model predictions are in excellent agreement with the angle-of-repose

measurements. The broader implications of these findings are discussed,

namely (i) the ability to obtain an accurate DEM

cohesion model from simple bulk experiments using a commercially available

instrument, and (ii) the applicability of these findings to continuum models

for cohesive particles in addition to DEM.

LIST OF

ABSTRACTS AND INDEX

Erasmo

S. Napolitano, Francesco P. Di Maio, Alberto Di Renzo

DIMES

Department, University of Calabria, Via P. Bucci, Cubo 42C, 87036 Rende (CS),

Italy

In the last decades, Discrete Element

Method simulations proved to represent a significant leap forward in the

capability to study and understand the complex hydrodynamics of fluid-solid

systems. Yet, despite the progress in the computational power and parallel

algorithms, their initial limitations on the number of particles still hinders widespread

applications to scale of industrial, if not pilot or even laboratory relevance.

Coarse-graining methods have been recently proposed to overcome these limits.

They act at the physical level, representing sets of actual particles by

larger, coarse-grained computational particles, or parcels, whose

properties are derived in order to capture the physics

of the original system. In the last years, coarse-grained simulations have been

applied in very different fields, from dense, quasi-static systems to bubbling

or fast fluidized riser reactors, and included thermal and reactive effects, as

well as scaled properties for cohesive flow, showing orders of magnitude lower

computational savings. In the face of an enormous potential, the ability of

coarse-grained DEM to accurately represent the complexity of granular and

multiphase flows has not been proved under all conditions and, especially, at

all levels of coarse graining. This lecture summarises the approaches, the

advantages and limitations of coarse graining strategies and levels, presenting

applications of the method in riser flow and cyclones. Open problems are

identified and discussed in detail along with directions for future

developments.

LIST OF

ABSTRACTS AND INDEX

Behrad Esgandari1, Stefanie Rauchenzauner2,

Christoph Goniva3, Rouven Weiler4, Simon Schneiderbauer1,2[1]

1Department of

Particulate Flow Modelling, Johannes Kepler University Linz (JKU), Linz,

Austria

2Christian Doppler Laboratory for Multi-Scale Modelling of Multiphase

Processes, Johannes Kepler University Linz (JKU), Linz, Austria

3DCS Computing GmbH, Linz, Austria 4 BASF SE,

Ludwigshafen, Germany

Keywords: Spout fluidized bed, KTGF, CFD-DEM, Experimental validation

Spout fluidized beds have been employed in

various processes, including gasification, chemical looping combustion, and

catalytic oxidation. Spout fluidized beds take advantage of both spouted and

fluidized beds, enabling them to enhance particle circulation and mixing as

well as action in wider operating ranges with less flow rate in comparison with

other beds.

In the past decades, two main modelling

approaches have been used to analyse spout fluidized beds. On the one hand, the

Eulerian-Eulerian approach (e.g. two-fluid model, TFM), where both phases are

treated as interpenetrating continua and the particle collisions are considered

by the kinetic theory of granular flows (KTGF), is preferably used for larger

scales. On the other hand, the Eulerian-Lagrangian approach (e.g. CFD-DEM),

where the gas phase is considered as continuous phase and the particles are

tracked individually, is commonly used for more detailed descriptions.

In the present study, we compare the

predictions of TFM and CFD-DEM with experiments for multiple spout beds [1].

Thereby, we employ OpenFOAM in the case of TFM, where new boundary conditions

(Schneiderbauer et al. [2]) and frictional models (Chialvo et al. [3]) have

been implemented. In the case of CFD-DEM, the open source framework

CFDEMcoupling is used. Computed time averaged velocities show fairly good agreement with PIV and PEPT measurements.